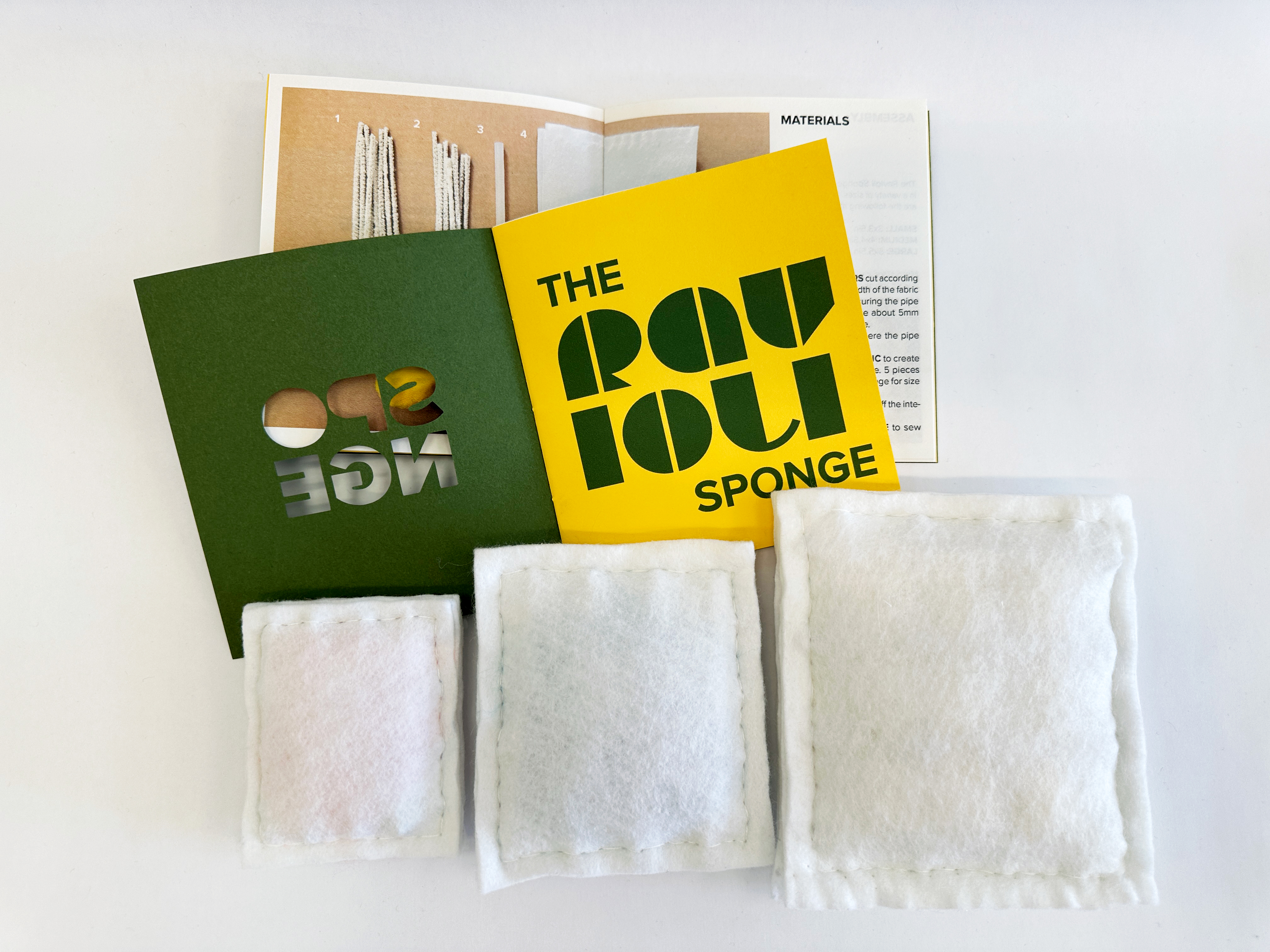

the ravioli sponge

(scroll to see the whole development process)

a redesign of the common household sponge based on the functions and mechanics of the sea sponge through the lens of biomimicry. a booklet was created as supplementary material to explain the construction of the newly designed sponge.

biomimicry design

typography

publication design

bookbinding

biomimicry design

typography

publication design

bookbinding

the process

round 1

intensive research was done on how a sea sponge and a regular sponge actually absorb water. the mechanism comes down to the multitude of pores that make up the body of a sponge, which in turns increases surface area, which allows the sponge to absorb more water. this became the basis of my hypothesis: if i create an object with a large number of small perforations that increases surface area like a sea sponge, it will absorb water like a retail sponge.

throughout my journey, the absorption factor (how much water my redesigned sponge can hold) also became my metric of success.

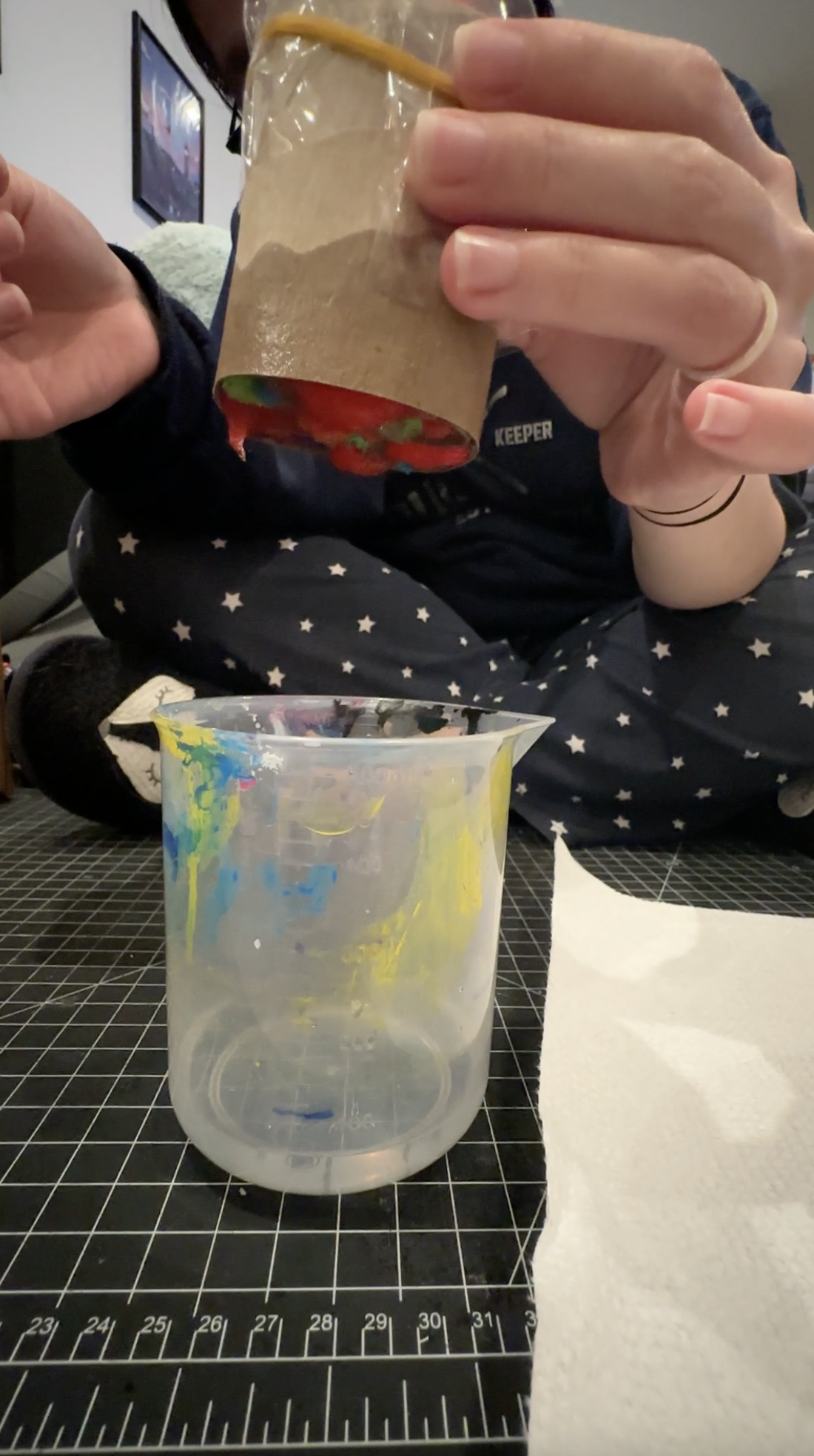

round 1 of sponge prototypes led me to this structure that mimicked the inside of a loofah plant. the water was able to move up the “sponge” via a suction mechanism that resembled capillary action.

but the sponge did not actually hold a lot of that water.

throughout my journey, the absorption factor (how much water my redesigned sponge can hold) also became my metric of success.

round 1 of sponge prototypes led me to this structure that mimicked the inside of a loofah plant. the water was able to move up the “sponge” via a suction mechanism that resembled capillary action.

but the sponge did not actually hold a lot of that water.

round 2

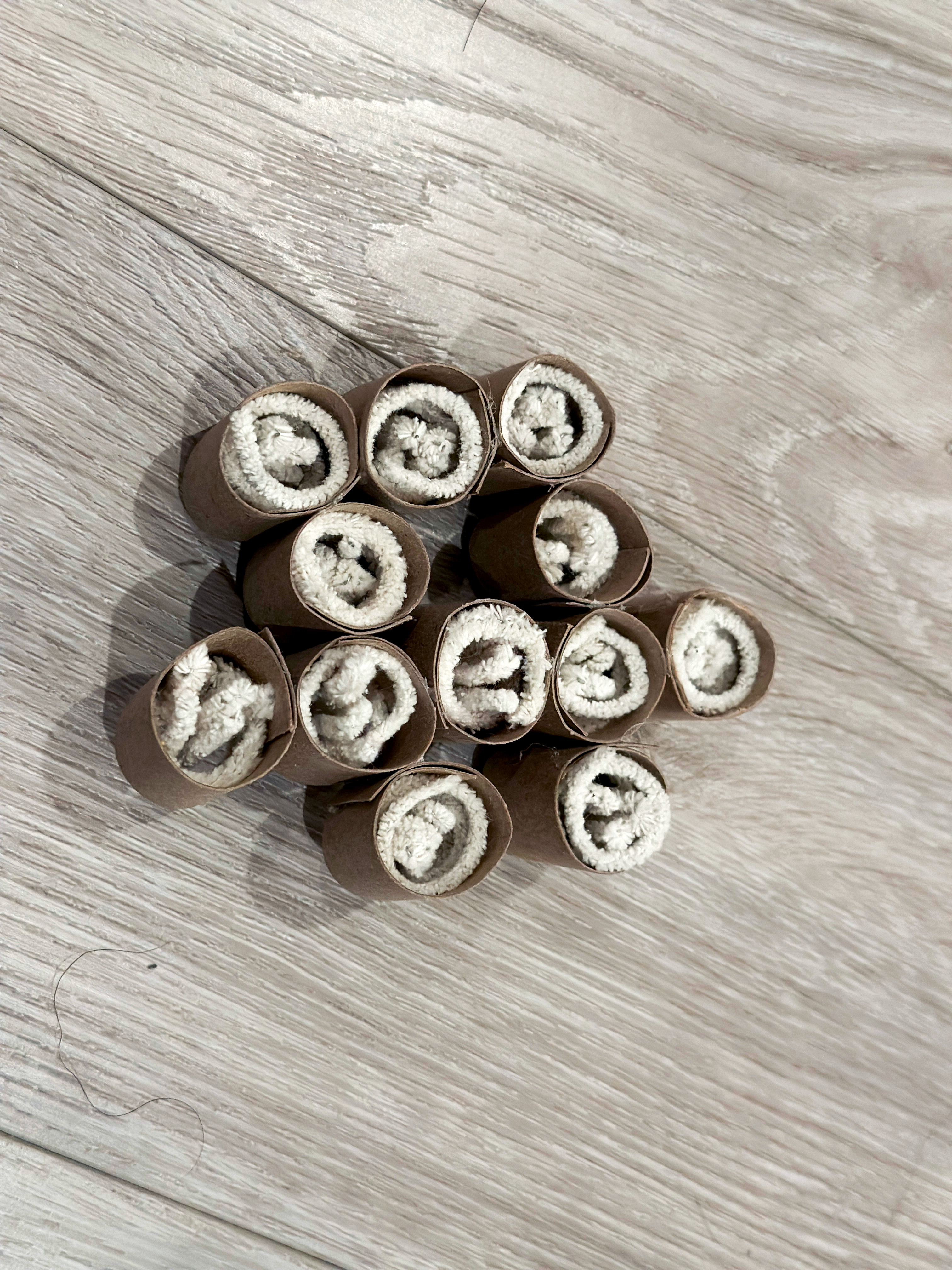

i proceeded with iterations on the same loofah structure by adding different materials to each new version. the materials selected were all ones that would increase surface area, which in turn would increase absorption.

1: straws, kraft paper, pipe cleaners, cotton balls

1: straws, kraft paper, pipe cleaners, cotton balls2: straws, kraft paper, pipe cleaners

3: straws, kraft paper, cat litter, coffee filter

(discarded after testing due to litter clumping)

4: straws, kraft paper, twine

5: straws, kraft paper, paper towels

6: kraft paper, pipe cleaners (2-3 twisted into a shape)

after testing, prototypes 1, 5, & 6 (left to right) had the best results with the most water absorbed.

but all of my results at this point were all qualitative. i needed to record quantative results in order to actually determine the best sponge design, which at this point i thought would be something that combined prototypes 1, 5, & 6.

round 3

round 3 saw me testing new materials, new structures, and new shapes.

1: pipe cleaners, kraft paper, felt

2: pipe cleaners, kraft paper, cellulosic fabric

3-4: pipe cleaners, kraft paper, cellulosic fabric, cotton balls

5: cellulosic fabric, paper straws

6: cellulosic fabric, pipe cleaners

7: cellulosic fabric, pipe cleaners, cotton balls

i started this round by testing which pipe cleaner shape from prototype 6 of the previous round was going to absorb the most water. each shape soaked in water simultaneously for the same amount of time then the volume squeezed out was measured.

shape 4 was the winner (pictured right) with about 8mL of water dispensed.

this round was also about testing more new materials and utlization of those materials to increase absorbency. i wrapped 1 prototype in felt and another in cellulosic fabric (prototypes 1 & 2), which is fabric made out of cellulosic materials (i.e. cotton, bamboo, etc.). the cellulosic fabric won dispensing about 20.5mL versus felt’s 17.5mL.

i applied pipe cleaner shape 4, the spiral, and the cellulosic fabric to 2 structures (prototypes 3 & 4 below):

![]()

![]()

![]()

the prototype 4 on the left that had an additional kraft paper layer dispensed 26.5mL of water, while prototype 3 on the right without the extra kraft paper layer dispensed 41mL. so far, that one was my winner.

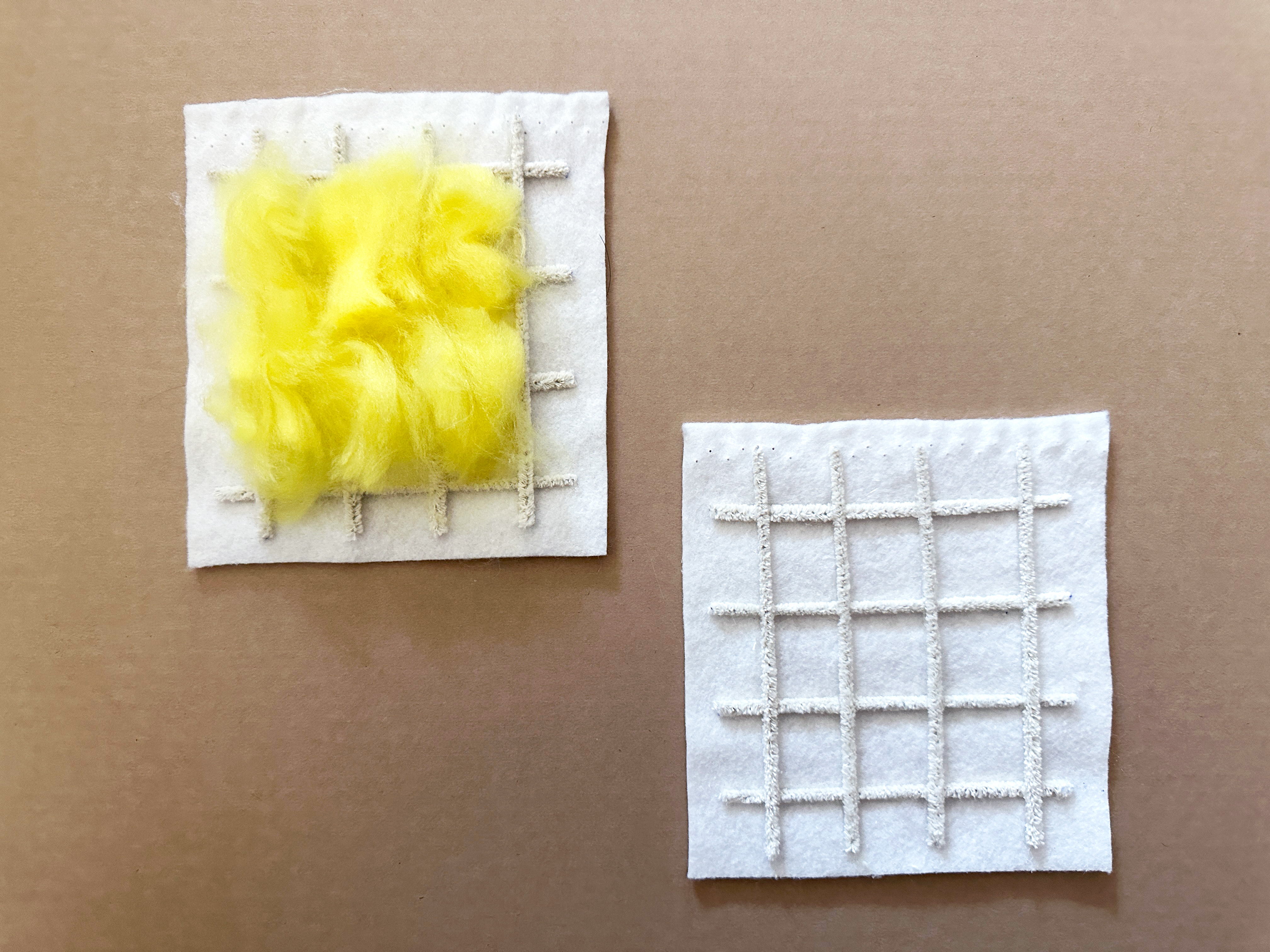

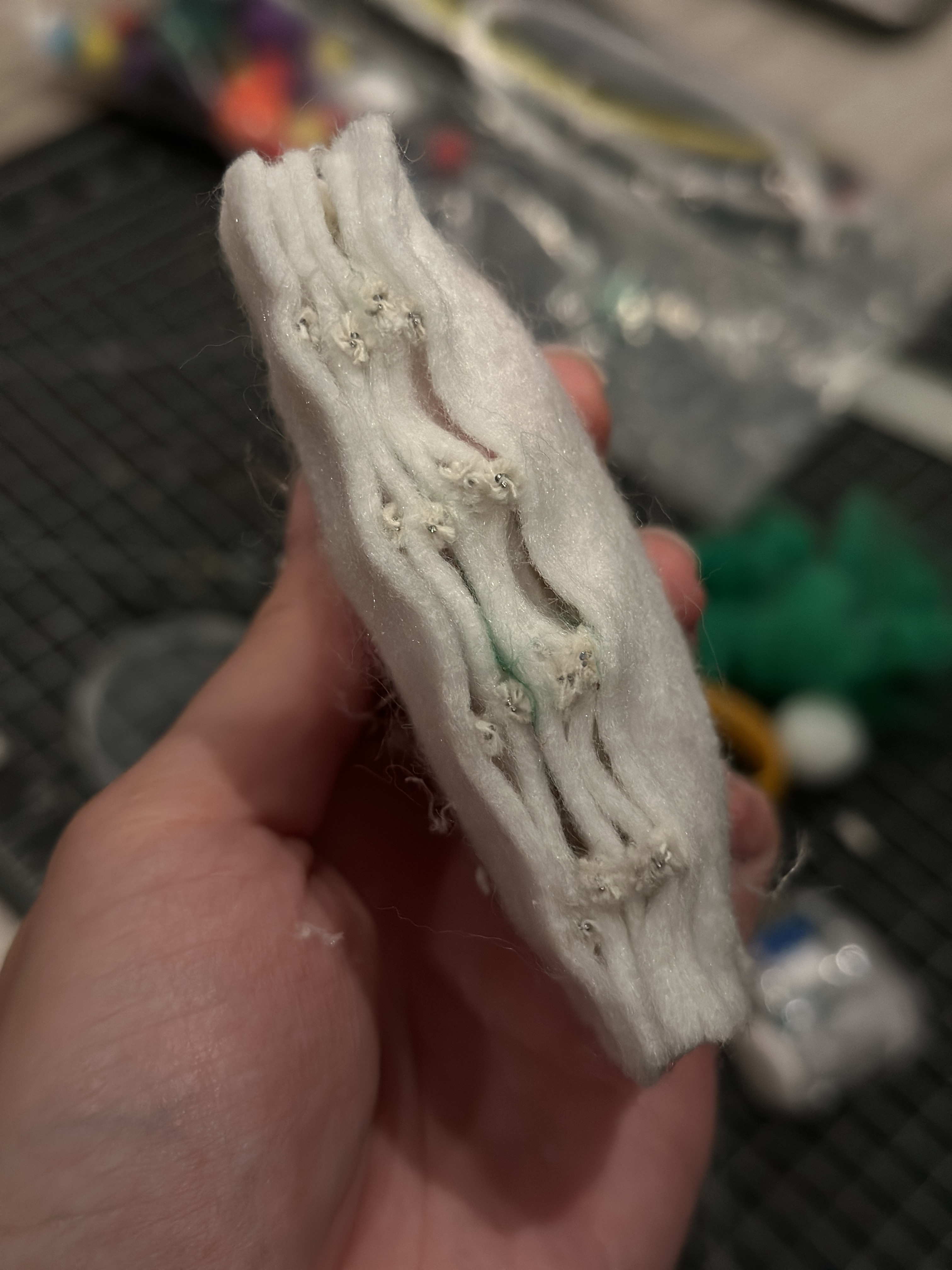

i moved onto testing the square prototypes (numbers 5-7), which came as a suggestion from a classmate to try a new shape that might increase surface area.

from left to right, prototype 5 had paper straws glued on the inside going only in one direction, prototype 6 had a lattice of pipe cleaners glued in every layer, and prototypr 7 had the same lattice structure but with cotton balls added.

this round was also about testing more new materials and utlization of those materials to increase absorbency. i wrapped 1 prototype in felt and another in cellulosic fabric (prototypes 1 & 2), which is fabric made out of cellulosic materials (i.e. cotton, bamboo, etc.). the cellulosic fabric won dispensing about 20.5mL versus felt’s 17.5mL.

i applied pipe cleaner shape 4, the spiral, and the cellulosic fabric to 2 structures (prototypes 3 & 4 below):

the prototype 4 on the left that had an additional kraft paper layer dispensed 26.5mL of water, while prototype 3 on the right without the extra kraft paper layer dispensed 41mL. so far, that one was my winner.

i moved onto testing the square prototypes (numbers 5-7), which came as a suggestion from a classmate to try a new shape that might increase surface area.

from left to right, prototype 5 had paper straws glued on the inside going only in one direction, prototype 6 had a lattice of pipe cleaners glued in every layer, and prototypr 7 had the same lattice structure but with cotton balls added.

surprisingly, prototype 7 (right) beat out not only all of the square prototypes, but also all the previous prototypes in terms of water amount held at a total of 85.5mL. this number was calculated using the weight of the sponge when dry, subtracted from its weight when wet, added to the amount of water it dispensed because 1g = 1mL.

in the case of prototype 7, dry weight = 29g, wet weight = 83mL, volume dispensed = 31.5mL.

83-29=54

54+31.5=85.5mL

in the case of prototype 7, dry weight = 29g, wet weight = 83mL, volume dispensed = 31.5mL.

83-29=54

54+31.5=85.5mL

round 4

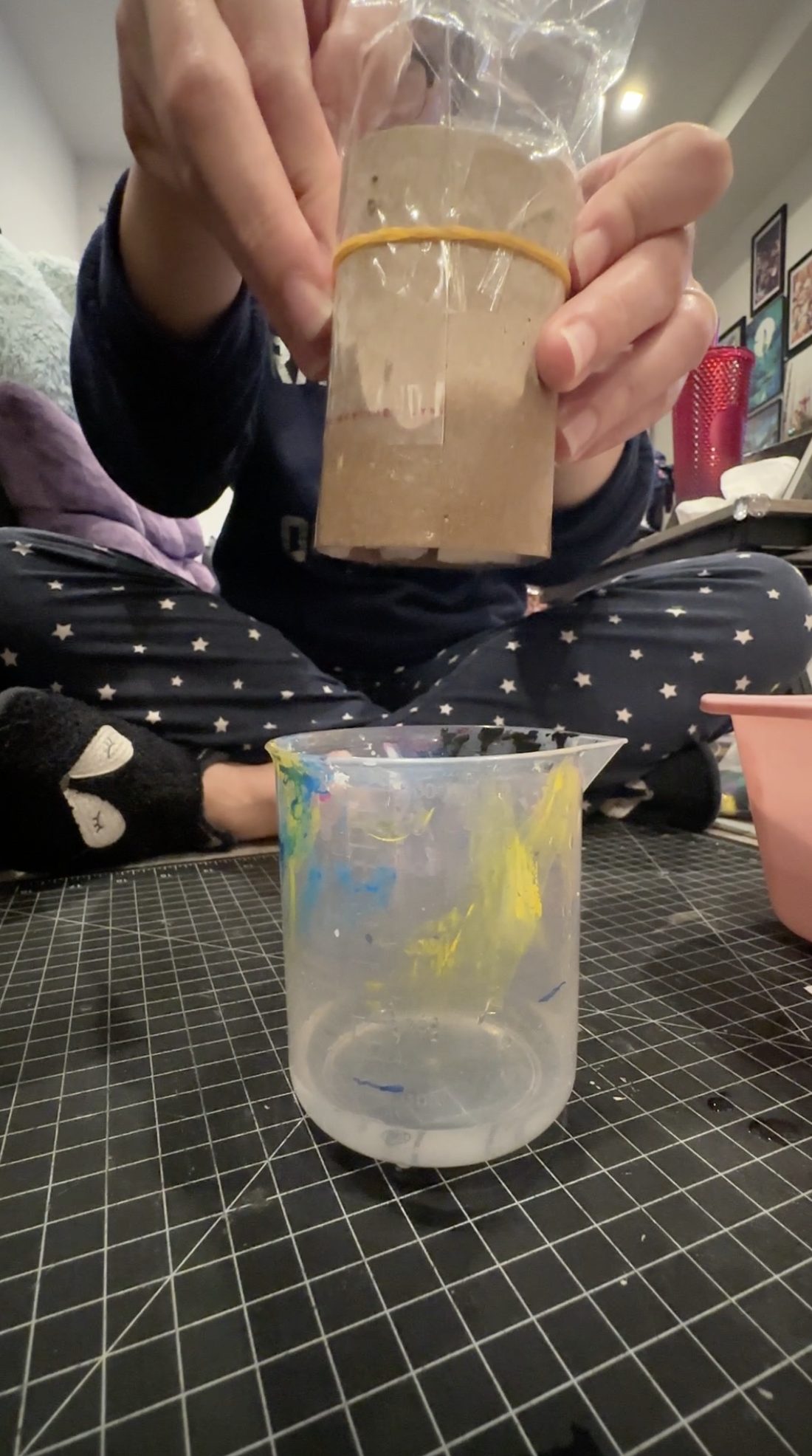

this round started off with some retests. due to inconsistencies in determining how much water was actually being absorbed by the sponge prototypes, i decided to retest the pipe cleaner structure and the previous 2 loofah-looking prototypes to make sure my results were accurate as possible using the weighing method i used on the square shaped prototypes.

in the retest, the pipe cleaner structure on the left (spiral with a core) actually turned out to hold more water at 7mL versus 4mL for the one on the right.

for the loofah sponge retest, the results were still consistent with round 3’s, with the one without the extra kraft paper layer winning at 118mLs of water held.

i decided that in order to be as thorough as possible, i needed a prototype that bridged the gap between the loofah structure and the square structures.

for the loofah sponge retest, the results were still consistent with round 3’s, with the one without the extra kraft paper layer winning at 118mLs of water held.

i decided that in order to be as thorough as possible, i needed a prototype that bridged the gap between the loofah structure and the square structures.

so i created a circular sponge prototype that had the same internal structure as the loofah one. after testing, this one was the clear winner with about 163.5mL water held.

but the fact that it was double the size of the square prototype i was comparing it to (prototype 7 from round 3) didn’t sit right with me.

so i decided to make a bigger square sponge with the same inside mechanism/structure so that the sizes would be comparable.

and so the ravioli sponge was born!

after testing, this guy was my clear winner with 175mL of water absorbed. in a test against a normal, retail sponge, a ravioli sponge of similar size actually held more water (85.5mL vs 51ml).

according to my original metric of success, which was volume of water absorbed, i had redesigned a better sponge using biomimicry. the internal lattice structure of the ravioli sponge is inspired by the actual skeleton of a sea sponge and the addition of extra layers, cotton balls, and the usage of the cellulosic fabric had increased porousness, which increased surface area, thus increasing absorption. much like how a sea sponge functions underwater.

![]()

![]()

but the fact that it was double the size of the square prototype i was comparing it to (prototype 7 from round 3) didn’t sit right with me.

so i decided to make a bigger square sponge with the same inside mechanism/structure so that the sizes would be comparable.

and so the ravioli sponge was born!

after testing, this guy was my clear winner with 175mL of water absorbed. in a test against a normal, retail sponge, a ravioli sponge of similar size actually held more water (85.5mL vs 51ml).

according to my original metric of success, which was volume of water absorbed, i had redesigned a better sponge using biomimicry. the internal lattice structure of the ravioli sponge is inspired by the actual skeleton of a sea sponge and the addition of extra layers, cotton balls, and the usage of the cellulosic fabric had increased porousness, which increased surface area, thus increasing absorption. much like how a sea sponge functions underwater.